Training

Qustom Apps offers a training couarse for each application that it develops.

Each training is comprised of a combination of lectures and practical, hands-on workshops to be performed by the student. The training may be performed online, or at the customer’s location.

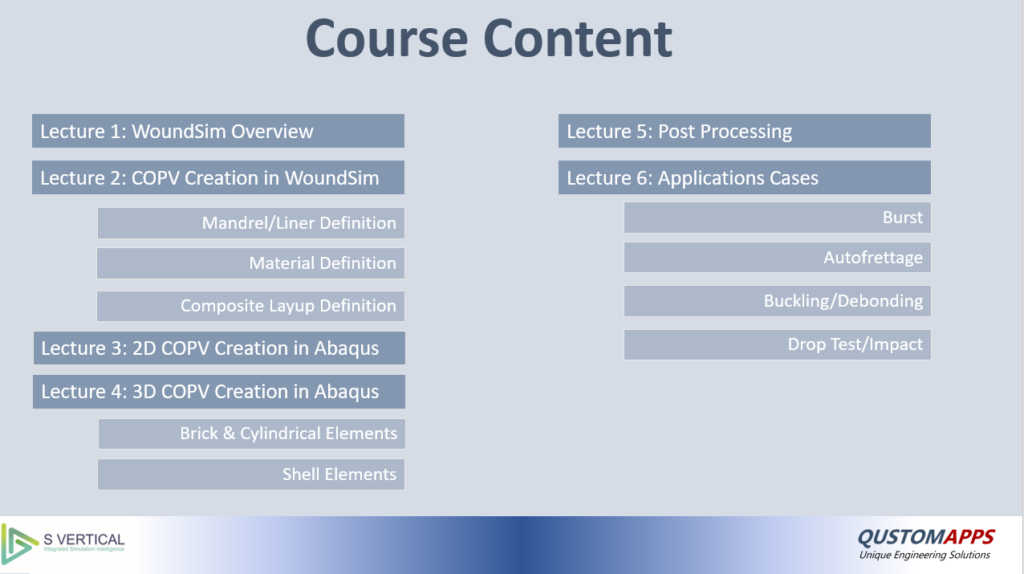

To the left is the course outline for the 2-day WoundSim training. The course begins by discussing the creation of the mandrel (liner) outline followed by the creation of the composite layup within the WoundSim GUI. Generating 2D and 3D Abaqus FEA models from the layup is then discussed. The use of continuum vs. shells, for both 2D and 3D, is discussed along with the special use case of cylindrical elements.

Post processing is covered to include how the smeared properties are computed and displayed, along with a discussion on the automated path plotting capabilities in the WoundSim/Abaqus translator. Finally, the course is concluded with a discussion on special applications such as computing burst/failure pressures and performing autofrettage, buckling, and impact analyses.

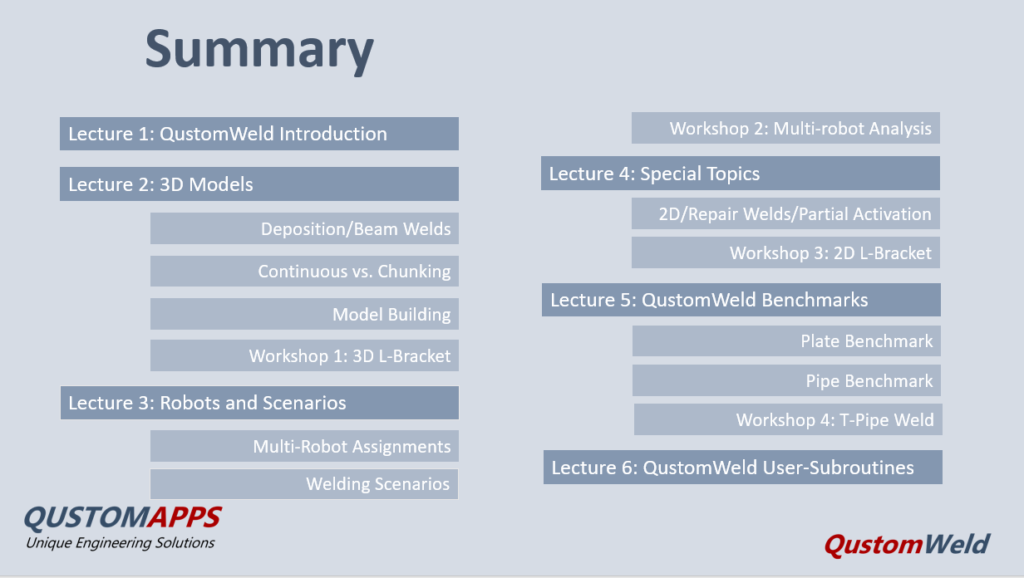

To the right is the course outline for the 1-day QustomWeld training course. The course begins with coverage of 3D models using an energy-based approach for simulating weld placement and energy inputs. The lectures covers the use of the types of torches including Goldak double-ellipsoid, constant flux, and temperature-based. To follow is a description of how robots and welding scenarios are used to define the way in which the welds are laid down during the simulation.

Advanced topics include 2D representations, phase transformation of base and weld materials, and partial element activation which is a method used to simulate welds with a large number of beads assigned.

A series of benchmarks are described and results shown using the various techniques available from within QustomWeld.

Our Clients