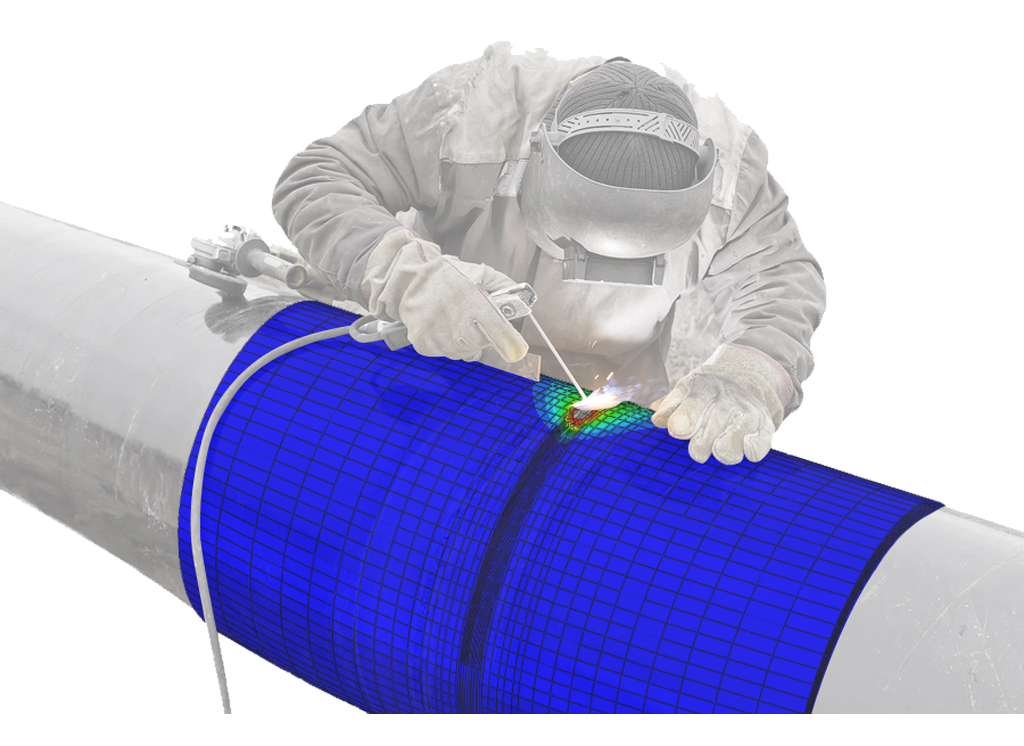

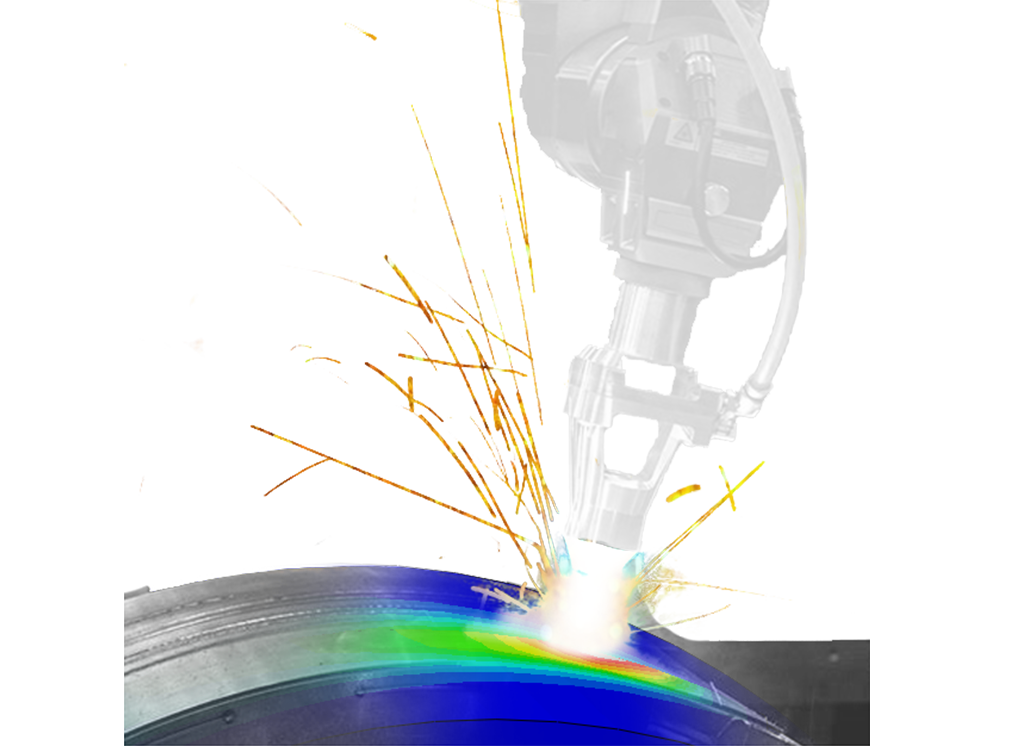

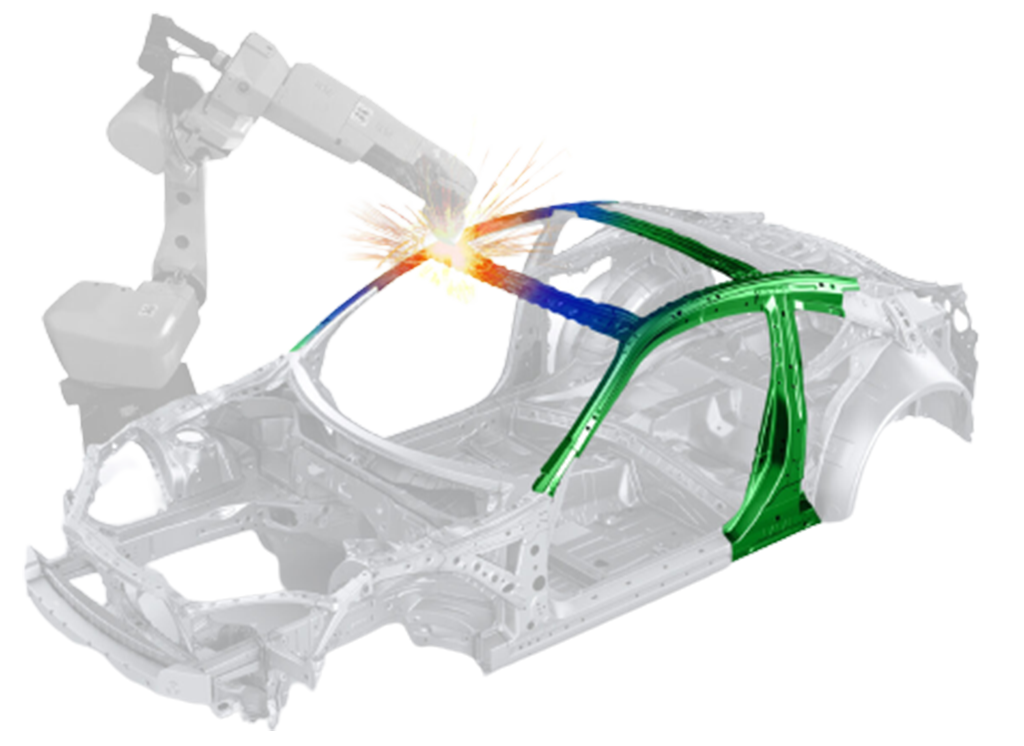

This welding simulation tool uses the latest solver technology in Abaqus

which was developed for 3D printing, to efficiently perform welding simulations. The GUI interface is fast, efficient, and very intuitive. Robot motions and welding characteristics are defined to control the input flux magnitudes and melt pool shape of the welding energy source. Welding scenarios control the sequencing of the welds by each robot.

QustomWeld

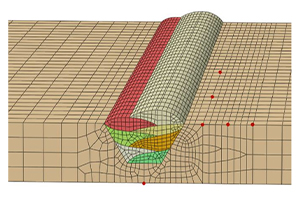

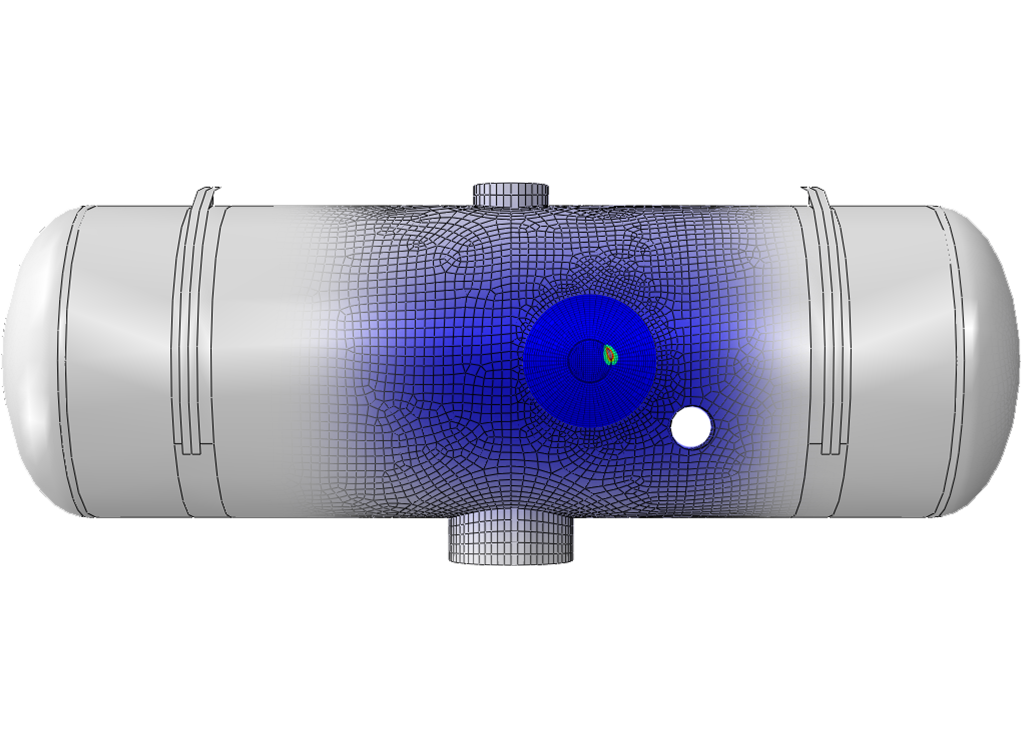

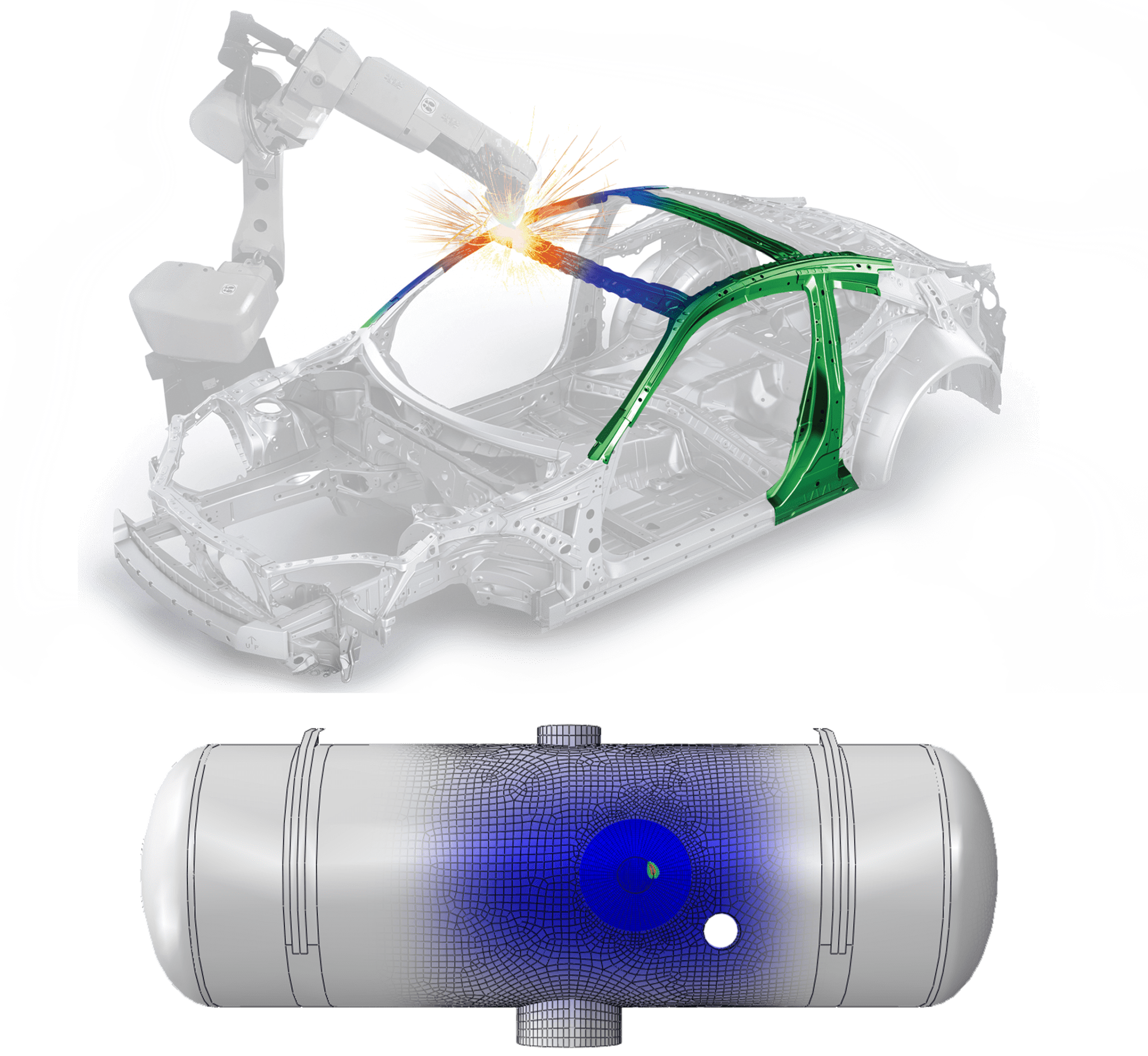

QustomWeld in an Abaqus/CAE extension (plugin) that automates the creation of 2D and 3D welding simulations within the Abaqus/CAE environement. The QustomWeld interface is designed around simulating an environment in which multiple robots lay down deposition or beam (autogenous) welds onto a structure simultaneously. Complex robot sequencing can be simulated, whether welds are laid down simultaneously, sequentially, or a combination of the two. Any of these is possible for one or many robots. While QustomWeld has been designed for the complexity of the situations just mentioned, its design still allows for simulating a general single weld application, provide as with any of the cases, general welding parameters are known.

QustomWeld Features

- Base Material: Selected by picking geometry or mesh. Model geometry can be imported as orphan mesh from 3rd party preprocessors

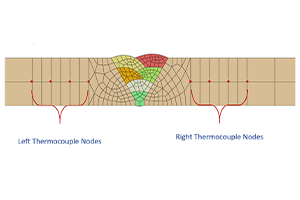

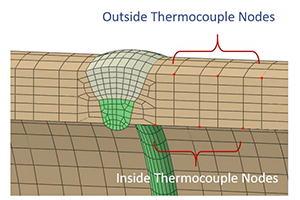

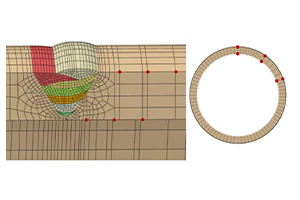

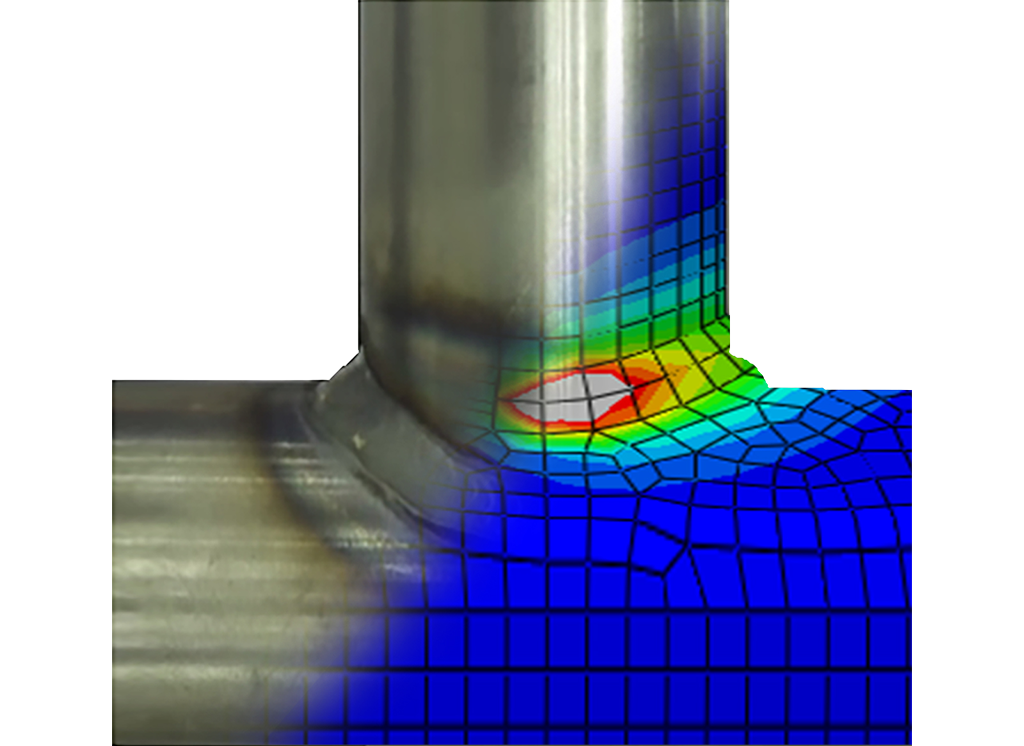

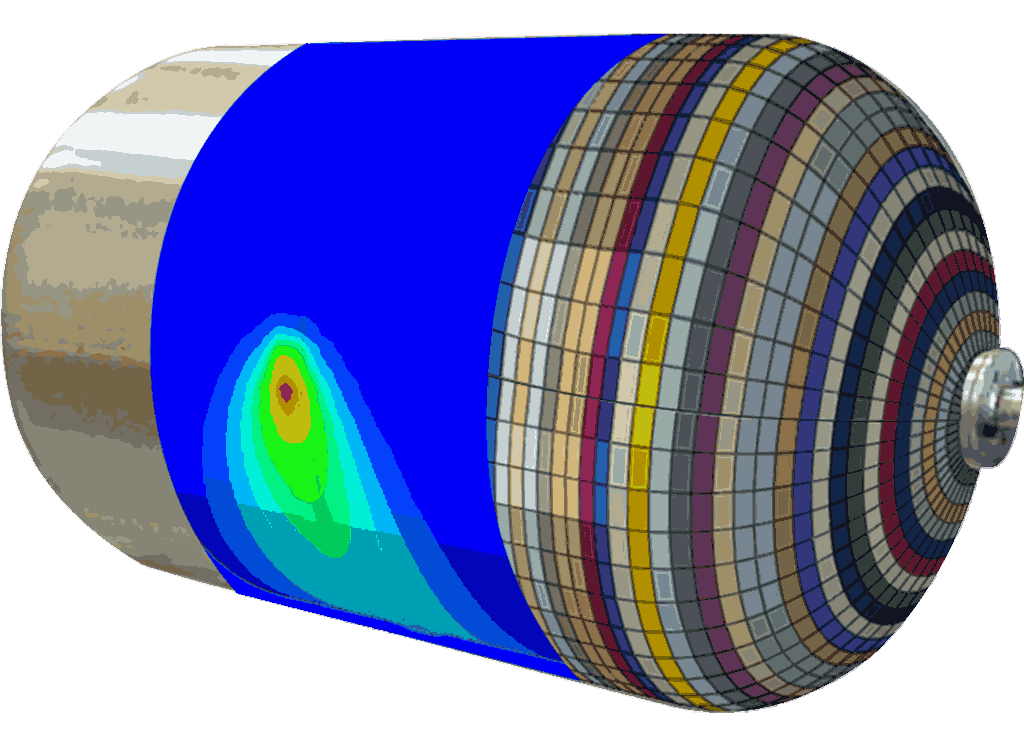

- Deposition Welds: Geometry or mesh-based. Torch normal can be automatically computed in a number of ways. Energy-based torch models such as Goldak, Constant-flux, or temperature-based (boundary conditions) for both 2D and 3D.

- Beam Welds: Multiple types including Layered-Pyo which is a general layered beam flux with an exponential decay of flux intensity similar to that of Goldak’s double ellipsoid torch.

- Robots: Welds are placed by assigning them to robots. The robot controls such as torch speed, energy input and dwell time.

- Welding Scenarios: These allow user to define multiple weld placement scenarios to assist in creating the optimal weld placement sequence.

- Analysis Controls: Extensive solver controls are provided to control the time integration and output of the analysis. Different controls for heat transfer and mechanical analyses.

- Fortran Library: All required subroutines are precompiled into a library so no Fortran compiler is required.

Benchmarks

An application brief and a number of benchmarks are available for viewing below.

An application brief describing in more detail the capabilities is also available in form of a .pdf file.

Video Demos

A number of informational/demo videos have been posted on YouTube to provide more information about QustomWeld’s capabilities. Below are the videos that cover most of the basic functionality of QustomWeld.

In addition, a number of benchmarks are available in for viewing in the form of PDF files.

Basic Model Creation Procedure

Deposition Welds in QustomWeld

Beam Welds in QustomWeld

Phase Transformation in QustomWeld

Our Clients